Most cruising sailors find that the lifestyle affords a reasonable amount of exercise. You don’t have a car, so you walk everywhere; you swim / dive – even fishing can be exercise when the fish gets to be 50lbs+.

This past week we discovered boat yoga. As we are staying here at Cabo to install the solar panels, we decided to knock down few projects ourselves. Foremost, the solar project requires wiring to be run from the upper aft deck of the pilothouse to the battery bank, which is in the forward bilge. As the proud N62 owners, Christine and I felt up for the challenge.

For the engineers – we’re running the panels in series – so we will have high voltage and low amperage to the controller near the batteries, and then convert the voltage down and amperage up for charging near the batteries with the solar controller (Outback 80). This is the most efficient way to get the volts / amps from the panels to the batteries. We spec’d 10 AWG marine grade tinned wire for the project.

100 ft of wire should work. We started the wiring from the middle – the electrical panel (just forward of the salon).

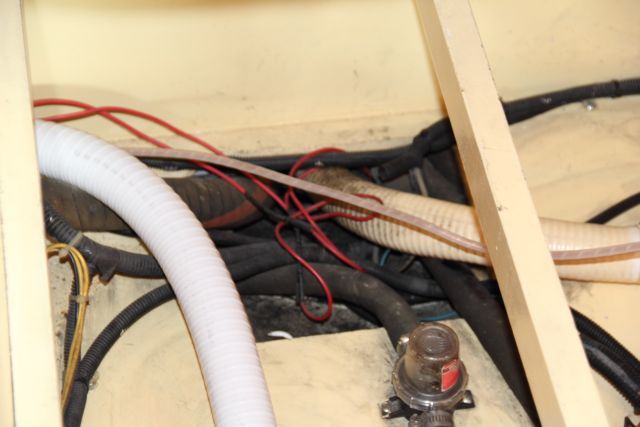

We identify two wires that go from the electrical panel to the batteries and decided to follow them . Oh my, they go WHERE? We open up every cabinet to trace them down. With a coat hanger to lead the wire, we made it into the starboard guest cabin.

Cabinet below the electrical panel.

The next Cabinet aft.

The Cabinet in the storage locker.

Under the bed in the starboard guest cabin. Drilling was involved.

Now to the mid-bilge (this is a special place on the boat: holding tank, hot water heater. bilge pump, fresh water pump). And yes on an N62 – it’s more than 6 feet deep from the floor. I see the wires coming in – but they are hopelessly out of reach. Christine attaches our valuable 140lb test monofilament fishing leader to the end of the cable – and feed in about 6 feet of leader. One piece of it makes to where I was balancing between the lower edge of the holding tank and the lower edge of the water heater neck deep in the bilge. Ok – a little push through the silicon seal between the mid-bilge and forward bilge to the batteries. Three hours and we’re half done with about 10 feet of cable to spare.

Made it! – mid-bilge.

All the way to the batteries! – our trusty monofilament leader.

Lunch time – and phase 2. We take the remaining 50 feet and feed it into the engine room with the other cables from the panel. Following cables and the hose from the pilothouse toilet we feed the cable through the outboard side of the engine room storage cabinets. This would be oh so easy if they hadn’t put an engine in the engine room, and filled up the storage cabinets – oh yeh – let’s put the hydraulic tank in front of one of the cabinets – humm – good place for the watermaker here in front of another cabinet. After a grueling two hours we’ve run another 10 feet and we’re at the “base of the stack”. Looks easy – everything runs up the conduit next to the exhaust stack.

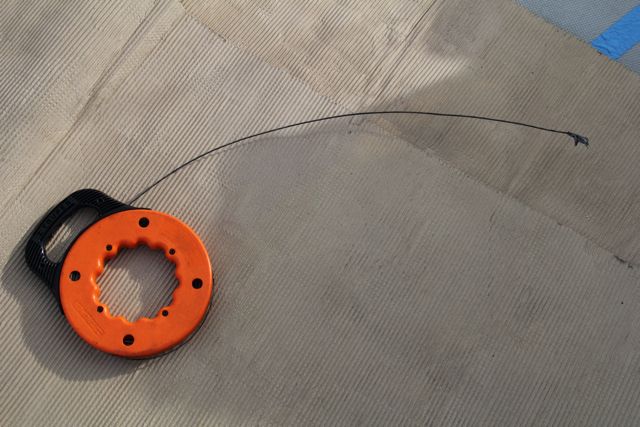

We borrow the 20 foot “plumbers tape” – (a coiled wire gizmo) which should help us fish the wire up the stack conduit.

We slide it in the opening at the top of the stack in the pilothouse bunk room…

…feed about 10 feet in – where it’d go? Ok let’s pull it out… what, it’s STUCK!! You got to be kidding. Two hours later no progress – time for Margaritas.

A strong cup of morning coffee encouraged another look in the stack access door in the salon – I can see the 20 feet of plumbers tape wrapped around the exhaust pipe of the engine at the top of the stack. Ooooo – what’s that at the top of the stack housing – looks like a door. Sure enough from the pilothouse aft outside locker there is a door – where the screws are still painted from the factory…

We pull the useless plumbers tape out (only an amateur would admit to the boatyard there tape was nearly lost) – it was hopeless tangled up.

We tied some fishing weights to the spool of 140lb test monofilament leader – Christine started feeding it down the stack conduit from the access door. I was laying on my back jammed in behind the main engine – hugging the wing engine (it would be a lot easier without those engines in the way), I can hear weight leader coming down the stack – bonk, hits me in the face. Done – 100 feet of wire run – we have about 10 feet to work with at the pilothouse deck – so 62 feet of boat takes 80 feet of wire.

We felt like we had just done 8 hours of body combat at the gym.

Other boat yoga practices include

- Cleaning up the teak rails.

Before

after

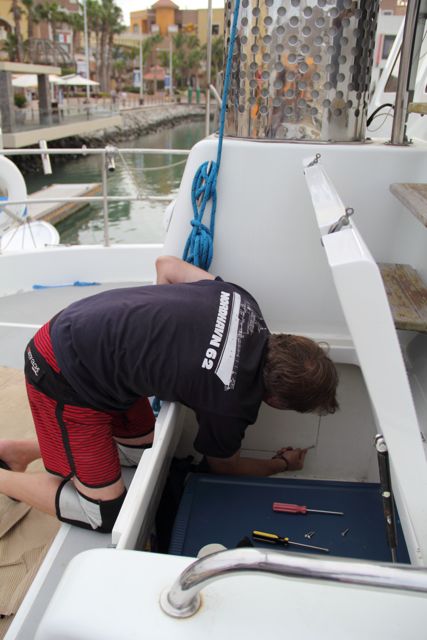

- Fixing the missing scupper door.

Before

Boat yoga pose

after

Glad to see its not all play 🙂

How many volts will the panels be putting out? 10 AWG over 100′ feet seems really great it must be very high?

Nice to see the scupper door back.

I was inspired by you guys and i’m working on putting in a dish-drawer in our galley. There seems to be space enough behind the engine on a platform that is meant for the genset. The prior owners had a cabinet mounted there, and also the old grunert refrigeration compressor was taking space.

The solar panels are rated for 235W each, ~30V and 8A. Connected serielly they should put out 120V and 8A at peak.

Good luck on the dish washer. They are nice to have – although most time we just hand-wash and use it as dish racks … One drawback – underway, the drawers tend to slide out when the sea is rough – duct tap works really well there.

Got it installed Sunday –

I bought the integrated model so I could put a custom front panel on it, and then add a latch to the front panel. Since its opens abeam it is a big issue on the sailboat where we are supposed to heel over 🙂

The current mounting point is also behind some doors to the engine room, but I didn’t want the possibility of the drawer banging against those doors in rought seas.

Another option I was considering was to incorporating a strap + snap around the top/bottom could be tucked away when not underway. I think the latch will be good though.

Boat yoga pose–love it.

Have an enjoyable and safe passage Mark and Christine. Really looking forward to seeing you in the Marquesas.

Jen